In our research we strive to achieve synthetic control over functional nanostructures and to investigate their physical properties and their application as materials for energy conversion and storage. We try to accomplish this by means of manifold synthetic approaches ranging from wet chemistry to chemical and physical deposition. To deepen our understanding of the working principles of materials and devices we employ a diverse line-up of analytical techniques to study important characteristics such as morphology, electrochemical and optoelectronic properties and structure-function relations.

The structure of our research is mainly divided in four different subgroups: Covalent-Organic and Metal-Organic Frameworks, Nanomorphologies, Photovoltaics and Mesoporous Nanoparticles for Biomedical Application.

NEWS

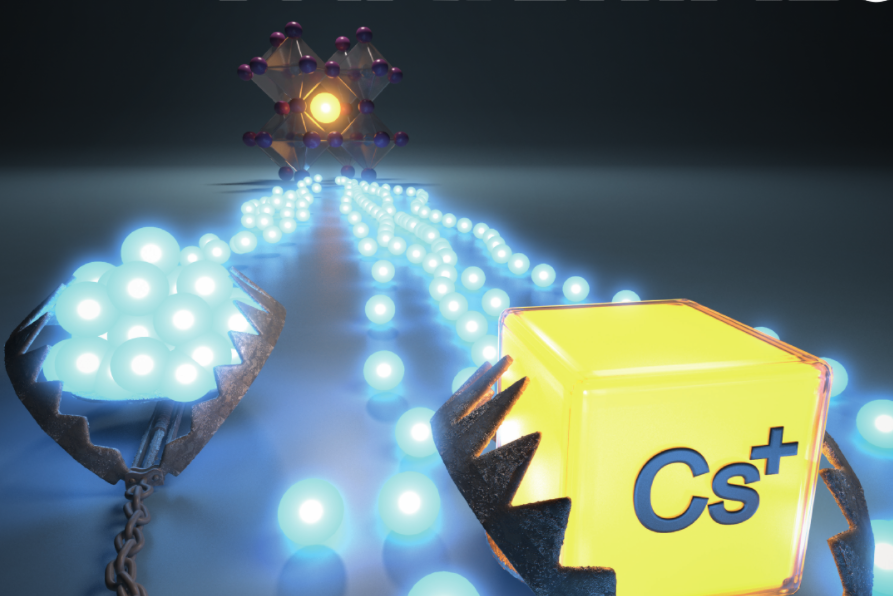

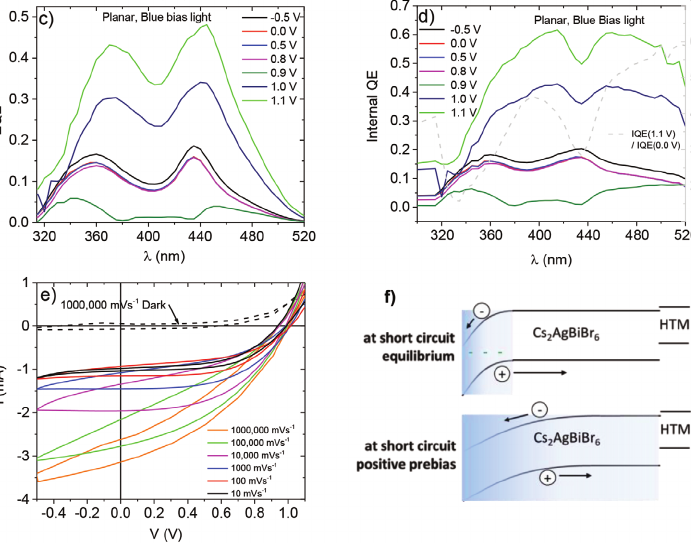

Message in a bottleneck: the performance limiting factors in lead-free perovskite solar cells

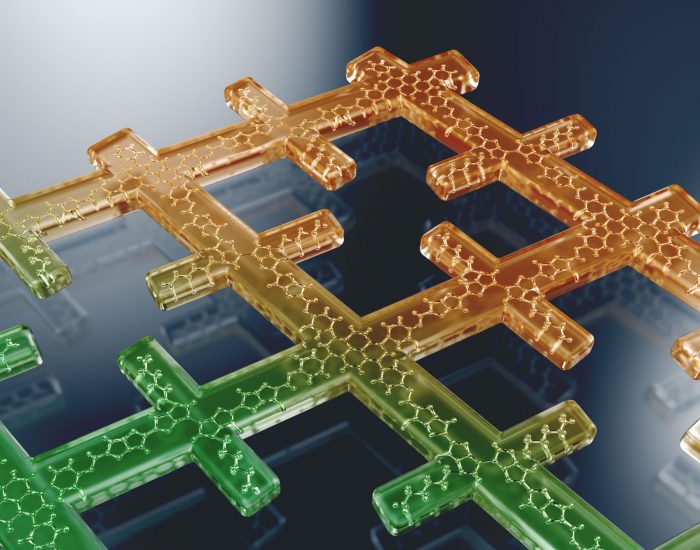

Message in a bottleneck: the performance limiting factors in lead-free perovskite solar cells Fast electrochromism in covalent organic frameworks: highly promising coatings for smart glass

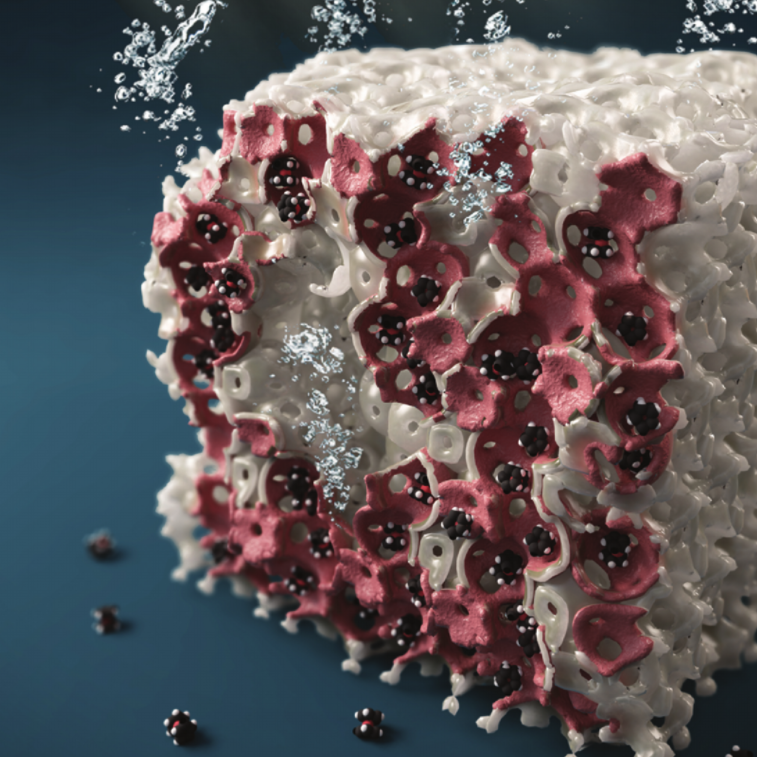

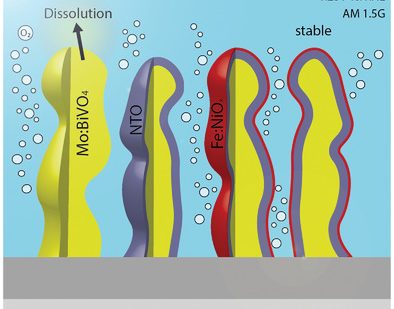

Fast electrochromism in covalent organic frameworks: highly promising coatings for smart glass Protect Ya Film: splitting water longer with ultra-thin coated Mo:BiVO4

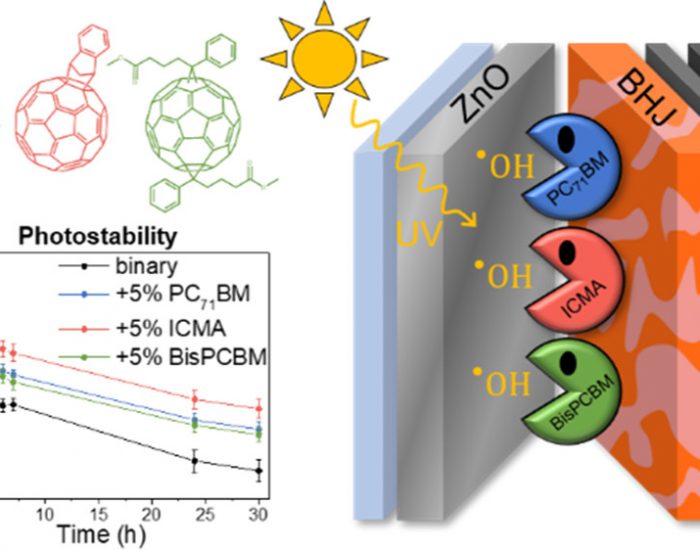

Protect Ya Film: splitting water longer with ultra-thin coated Mo:BiVO4 All good things come in threes: how Fullerene Derivative Additives drastically improve the stability of inverted ternary organic solar cells

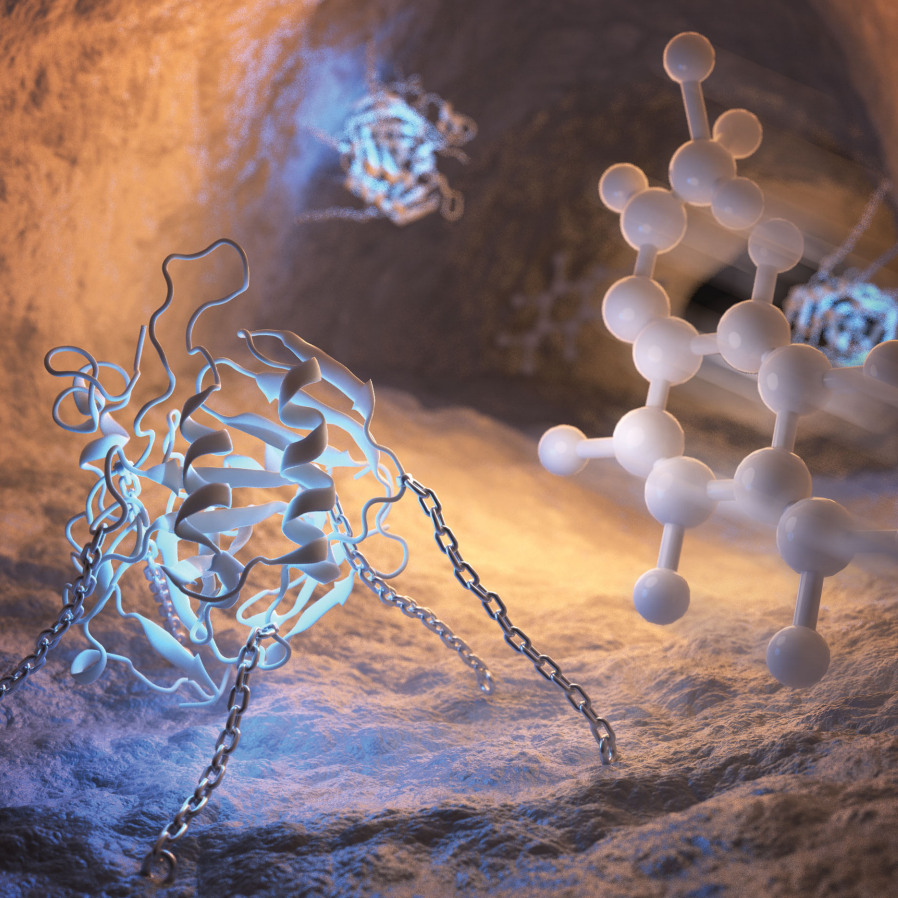

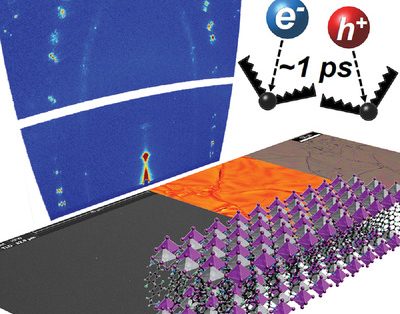

All good things come in threes: how Fullerene Derivative Additives drastically improve the stability of inverted ternary organic solar cells No need for GPS: Ultrafast carrier localizing in highly oriented thin films

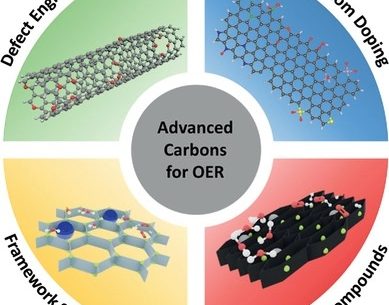

No need for GPS: Ultrafast carrier localizing in highly oriented thin films Carbon-based materials against the carbon footprint: the future of energy storage by water electrolysis

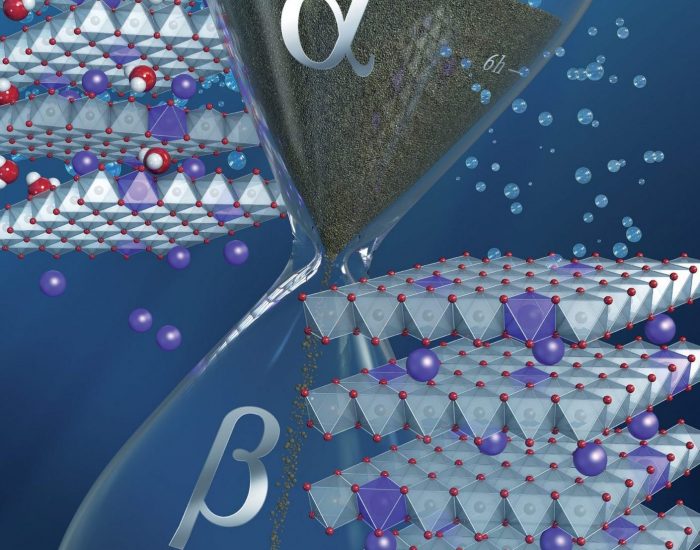

Carbon-based materials against the carbon footprint: the future of energy storage by water electrolysis V is for voltage: V(III)-doped nickel oxide based nanocatalysts, in depth:

V is for voltage: V(III)-doped nickel oxide based nanocatalysts, in depth:

Research topics in the group

Images by Christoph Hohmann